In this era where everything is getting computerized, and machines are there to make the industrial work easy, there is a Computer Numerical Control Router or CNC Router. As its name suggests, it is a computer-controlled machine which has the capability to cut hard materials like wood, metal, stone, polyurethane foam and many more.

The basics of CNC lies in the motor CNC, and the number of axes it is having which makes it useful for different purposes in different fields. Talking about the heart and soul of CNC, it lies in the type of motor it is using. It can be a Stepper or a servo kind of Motor. While both have its pros and cons, the stepper motor is considered more efficient due to its advantages over Servo motors.

Working

The CNC Router uses computer programs for its functioning. It is an efficient machine which minimizes waste and increases the productivity. A CNC Router can cut in three different axes simultaneously, which makes it beneficial for industrial purposes. The axes are:

- The longest among the axes is the X-axis which runs from front to back.

- Y-axis runs from left to right.

- Z-axis runs from right to left.

CNC Routers have significant use in creating complex shapes.

Types of CNC routers

CNC Routers can be used for a wide range of work. From performance they can be classified into four basic categories which are as follows:

- Industrial CNC Router Machine– Being widely used in the woodwork industry, these cover up to 80% of CNC Routers in the market and can be used to manufacture doors, furniture, etc.

- Mid Range CNC Router– Lighter in weight and smaller in size, they produce more precise and accurate products than industrial CNC Routers.

- Hobby CNC Router– These are the mini CNC Routers which can be made at home with some plans. Though building it takes too long, but it is much lighter, smaller and easier to use a type of CNC Router. Nowadays, these Hobby CNC routers are also available in the market for the convenience of the clients.

- Especially Designed CNC Router– To fulfill particular purposes of the Router there is this Specially Designed CNC Router in which specialty CNCs and multi-axis CNC are included.

Power of CNC Router

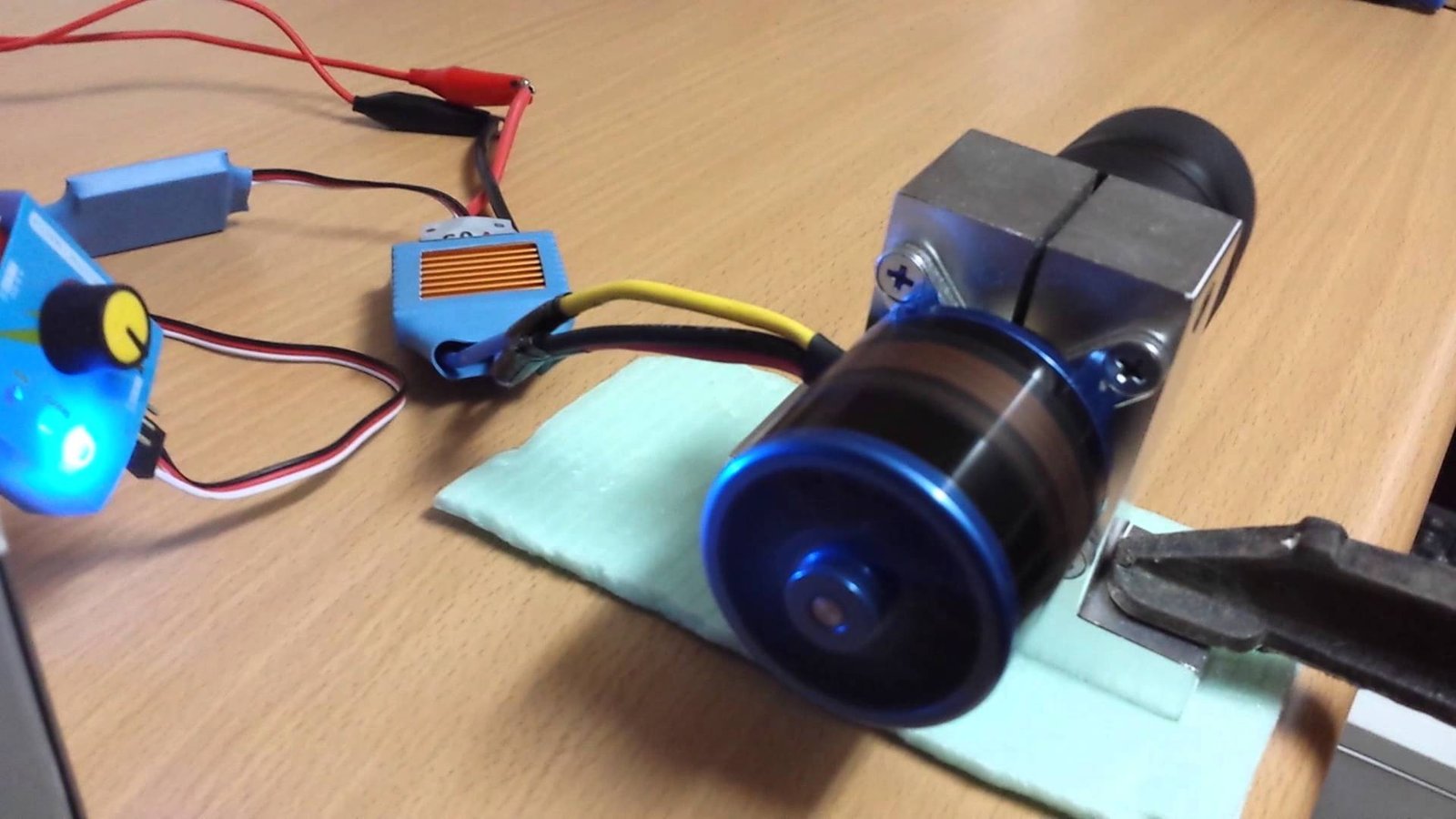

The most crucial part of the CNC Router is its power supply source which is its motor. Since, the type of motor being used in the machine tells about the accuracy, precision and the speed of the router, so it is essential to select suitable Router with the suitable motor. The two types of motors which are used are The Stepper Motor and The Servo Motor.

- Stepper Motor– This type of brushless DC motor is more versatile which gives a vast arena of usage. Being easy to use and lower in price it is more suitable for the customers. Moreover, its abundance and advantages over the servo Motor make it more reliable.

- Servo Motor– Though it uses the same power as that of Stepper Motor it comes at a higher price but with a larger frame. It has brushes which make its lifespan shorter than that of Stepper Motors. It has encoders which are prone to failure. Also, its intricate design makes it less suitable for the use.

Both of the motors have its pros and cons, but they can be used efficiently in different environments for different purposes.

Since the CNC Router uses computerized working of the machine, it makes the industrial work easier yet efficient. There are various classes of CNC Routers which are used according to the task. Most wide application of it is in the wood industry, but it can also be used for cutting of other materials. The usability of a motor CNC can be increased by different motors CNC uses. So, it is a very advantageous machine to fulfill industrial purposes.